Biogas Plant Model - Learn the Working of Biogas Plant in 3D Metaverse

Energy is an important chapter for science students. Due to the increase in global warming and pollution, the search for clean and renewable energy sources is increasing. Biogas is a good example of a zero-waste energy source that offers economic and environmental benefits.

What is Biogas?

We can break down organic matter into gases to produce a renewable energy source. These gases are methane, hydrogen, and carbon-di-oxide. The organic matter can comprise food waste, manure, seaweed, paper, and agricultural waste.

Bacteria are introduced into the waste under anaerobic conditions to produce these gases. This becomes an energy source and is termed biogas. The sludge, which is produced as a by-product, is used as fertilizer.

Biogas effectively decreases the load on landfills and cuts down the toxicity from sewage plants as well. During the process of conversion, methane toxicity is reduced by converting it into carbon-di-oxide.

Biogas Plant Model

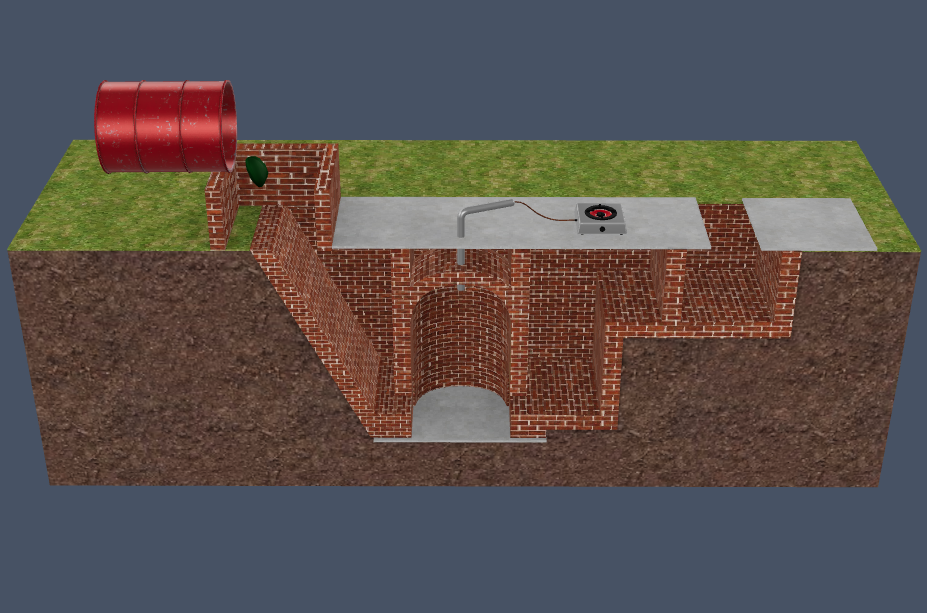

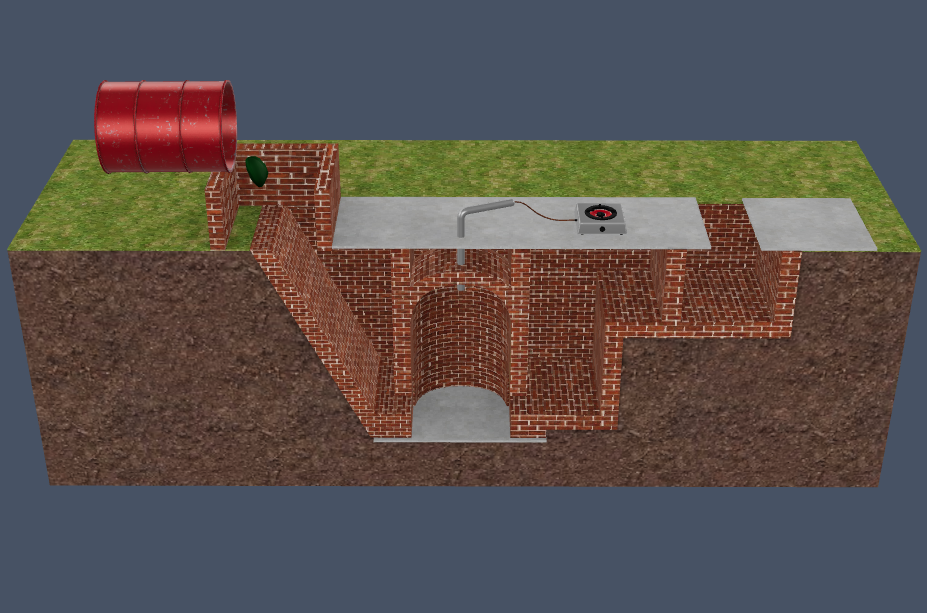

Students who view a biogas plant model in metaverse will understand its structure and functioning well. A biogas plant enables waste energy to be converted into an eco-friendly energy source that provides energy and fertilizers.

A biogas plant model 3D has five main constituents that enable biogas production. These are:

An inlet- To feed the slurry

A reception area- This chamber receives the raw materials to prep them and enables the process of anaerobic digestion and fermentation chamber. Different materials or biomasses undergo different fermentation processes.

Hence the length of time to produce the biogas varies according to the input matter. Nowadays, many industrial plants accelerate the process through pre-treatments.

A digester fermentation tank- A digester fermentation tank/ gas holder is an airtight tank where the fermentation process takes place. The tank is fitted with agitators that help churn and move the biomass to release the gases.

The biomass is fed into the water-filled digesters to create an anaerobic environment. The breakdown of organic matter then takes place so that the gases can be released.

Outlet Pipe- The outlet pipe helps evacuate the digestate or slurry left after the gases have been released.

Exit Pipe- The exit pipes release gases to specified locations.

Biogas Plant Working

Students keen to understand how a biogas plant works can view a working model in the metaverse. They can visit virtually to understand the biogas plant model 3D rendition.

By visiting the plant in the metaverse, they will be able to see first-hand how the biogas plant functions.

Let’s take you through the major steps involved in biogas plant work.

The Digestion Process

The collected waste organic matter called substrates is first pre-treated if required. They are then sent to the digester tank for anaerobic fermentation. The substrate includes matter like manure, agricultural waste, crop wastage, food wastage, etc.

Depending on its size, a biogas plant can have multiple digesters.

The Fermentation Process

The organic waste matter or substrates are exposed to varying degrees of temperatures. The environment is devoid of light and oxygen to facilitate the process. The bacteria or microorganisms are simultaneously mixed into the matter.

These bacteria start working on the substrate and break down the organic matter. Agitators ensure the frequent movement of matter to prevent layers and ensure complete breakdown uniformly.

Biogas Production Process

When the fermentation of the organic waste matter occurs, it releases harmful gases like methane and carbon dioxide. Due to the presence of hydrogen sulfide as well in the waste matter fermentation process, containers are made of heavy and enduring metals to contain these gases.

Residual Extraction Process

After fermentation, the residual matter, or digestate, is extracted. Since they are rich in nutrients, they are further used as fertilizers. The biogas plant enables lesser loads in landfills and carries out zero waste.

Cleaning Up Process

The biogas is then treated to clean up the process to remove water, hydrogen sulfide, and other impurities. The biomethane is left and extracted to generate energy and heat.

A continuous quality audit of the biogas is being produced to ensure that it is free of impurities.

These are the main steps in a Biogas Plant Working Model. Students can view it interactively in a biogas plant model 3D form and learn the working of biogas plants in the Metaverse.

Frequently Asked Questions

What are the advantages of biogas?

Biogas plants benefit the economy and are environment-friendly. It is a renewable energy source and offers clean and carbon-neutral energy. Biogas can be used as an energy source in industrial and household applications.

Is methane released during the biogas production process?

Methane is not released into the atmosphere, and biogas production leaves no negative environmental impact.

What are the benefits of learning about biogas production through a biogas plant 3-D Model?

Students have to learn about various forms of renewable and non-renewable energy sources. These are important chapters. When they view and undertake a virtual visit of a biogas plant in the metaverse, they can experience first-hand the working of a bio gas plant. This allows them to retain information for a longer time.

How is Edverse facilitating metaverse education?

The Metaverse is an alternate or virtual reality that can simulate our physical environment and objects through digital twinning. Moreover, the metaverse offers an expansive and shared, environment. The metaverse offers many applications.